Keep it simple

Because these are prototypes, there is an assumed iterative process. Cards will be tested and updated to reflect gameplay changes or tests often, so we need to make the process easy to modify. Others may suggest gluing fronts to backs, sealing in plastic or printing on heavy card stock. We have decided to sleeve our prototypes.

The card

First, just how big is a card for most games? We have decided to use a standard poker sized card, 2 and a half by 3 and a half inches. There are other options but this one seems to work best for us.

The layout

We use one of our favorite image editing and illustration programs to layout a 3 by 3 grid of cards on a standard piece of paper at 300 dpi. This gives us 9 cards per page and 6 pages make a complete standard 54 card deck. Download our template here.

Card contents

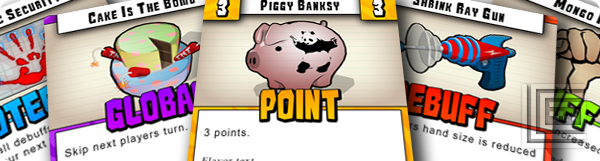

Each card requires a few important things on them.

Card specific rules, printed in a clear clean font.

At least one visual indicator (picture, icon, etc…) for the other players to quickly identify what has been played. A deck of plain white cards with black text all look the same and make the testing experience un-fun. This could be color or a picture.

Hey we didn’t say it has to have a name, nope we didn’t, normally the name is flavor and not relevant to gameplay..

To the printer

We load the printer with generic plain paper. Since we have color and graphics included we normally print in full color, but draft mode is normally clear enough. For our own sanity in the cutting process later we print slightly scaled down, at about 95%. scale.

Cutting out the cards

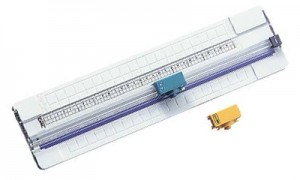

We have tried a number of tools for cutting out our cards, scissors, a standard paper cutter, a guillotine paper cutter, roller cutters and more. For us, the best bang for the buck for our time and effort, is a rotary trimmer.

Final assembly

First we place one of the cut-out prototype paper cards.int the sleeve and then add an old playing card or game card behind it for structure. Without the extra card for reinforcement the sleeves feel flimsy. Also worth noting, the slightly scaled down print makes the paper portion fit more easily into the sleeve.

The finished deck

Decks comprised of cards in sleeves all feel and shuffle the same, whether they are professionally made and printed linen cards or a paper facade in front of an old card. The overall parts cost is low, and the ability to recycle old parts makes this approach more sensible for us.